Product World

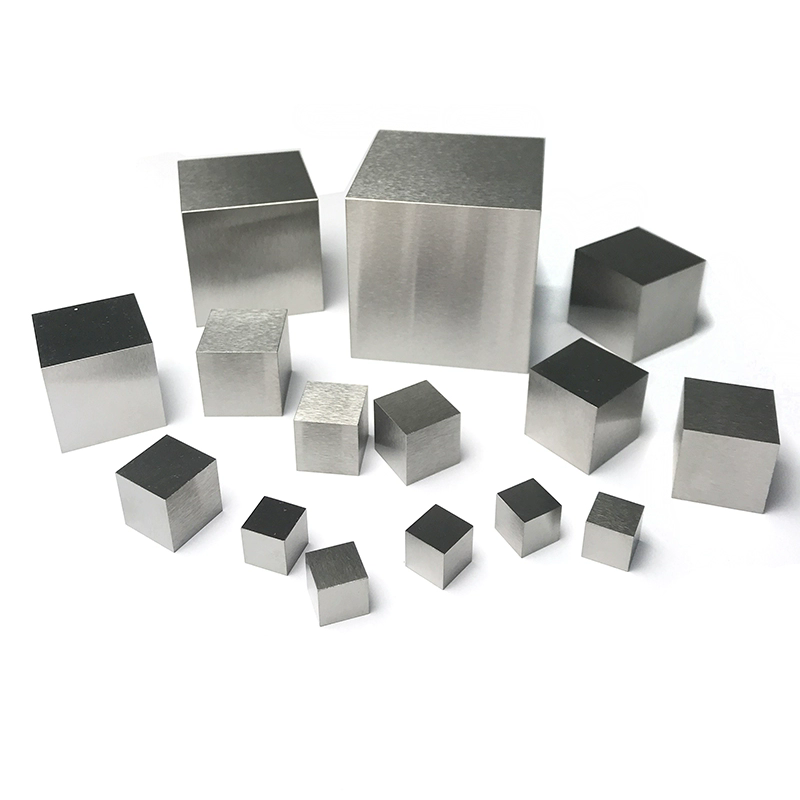

Tungsten Alloy Counterweight

WHA, High-density, WNiFe / WNICu, 17.0~18.5g/cc, Standard & Non-Standard, Support Customization

Key words:

Classification:

Tungsten Alloy Counterweight

Product accessories:

Hotline:

Tungsten Alloy Counterweight

Application of Tungsten Alloy

This property combination has made this alloy a candidate for defense and civilian applications. They are widely used in many fields such as the sports, including golf, fishing,darts, yacht, racing car; the medical, including radiation shielding, source holder, collimator, isotope container,nuclear syringe; the scientific, including tungsten heat sinks, oil drill, mine exploitation; also in military,including bullet, shrapnel head, balanced ball for missile and plane, etc.

Introduction of Tungsten Alloy

Tungsten alloy, also named tungsten heavy alloy, generally is refractory metal, which has two-phase composites consisting of W-Ni- Fe or W-Ni- Cu or even W-Ni-Cu-Fe, some tungsten alloys are added Co、Mo、Cr, etc. They have very high melting point and have a density twice that of steel and are more than 50% heavier than lead. Tungsten content in conventional heavy alloys varies from 90% to 97% and is the reason for their high density (between 16.5g/cc and 18.75 g/cc). Nickel, iron and copper serve as a binder matrix, which holds the brittle tungsten grains together and which makes tungsten alloys ductile and easy to machine. Nickel-iron is the most popular additive, in a ratio of 7Ni:3Fe or 8Ni:2Fe (weight ratio). The conventional processing route for tungsten heavy alloy includes mixing the desired amount of elemental powders, followed by cold pressing and liquid phase sintering to almost full density.

The majority of current usages for WHAs (tungsten heavy alloy) are best satisfied with the W-Ni-Fe system. As its high density, it is mostly used as tungsten alloy crankshaft for racing car weight. Tungsten heavy alloy such as 93W-4.9Ni-2.1Fe and 95W-4Ni-1Fe represent common compositions, and the addition of cobalt to a W-Ni-Fe alloy is a common approach for slight enhancement of both strength and ductility. The presence of cobalt within the alloy provides solid-solution strengthening of the binder and slightly enhanced tungsten-matrix interfacial strength. Cobalt additions of 5% to 15% of the nominal binder weight fraction are the most common.

With more than 70 years' successful experience, we has become a leading company could offering tungsten alloy products. As a professional manufacturer and exporter, we can not only manufacture products as per international standard, but also design according to customers' concrete requirements.

The Major Tungsten Alloy Products and Services

Tungsten Heavy Alloy (WHA, tungsten alloy)

✅ Tungsten heavy rod, bar, cube, brick, block, plate for various applications

✅ Tungsten billet/barrel as main body of professional darts,

✅ Screws/heads for golf club, flying fish sinker

✅ Counterweight used in yacht, sailboat, submarine and other vessels

✅ Ballast for aircraft, helicopter, F1 racing cars, and other vehicles

✅ Kinetic energy penetrators for defeating heavy armor

✅ Governor balance weight, holders for Oil Well Logging

✅ Cubes/balls for bullet, rifle, missile and bomb

✅ Radiation shield, source holder for nuclear U-power,X-ray, and medical instruments parts etc.

✅ Bobs/vibrators for mobile phone, clock

✅ Tungsten-thorium guide nozzles

Previous

Previous

WNiFe, Szie 2.5~180mm, 17.0~18.65g/cc, Machined, 30x20x15mm,50x20x15mm,60x20x15mm

WHA, High-density, WNiFe / WNICu, 17.0~18.5g/cc, Standard & Non-Standard, Support Customization

WHA, 17.0~18.5 g/cc, Dia 2.5~260mm, Non-toxic

Consulting price

Thank you for your trust in the northern alloy! Please fill in your requirements and we will provide you with service wholeheartedly.

* Note: Please be sure to fill in the information accurately and keep the communication unblocked. We will get in touch with you as soon as possible.