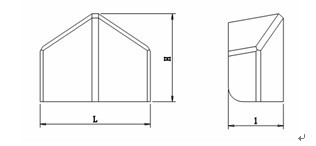

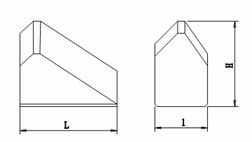

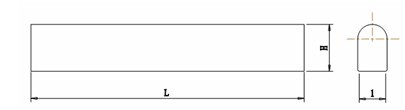

L | 1 | H |

50 | 25 | 40 |

60 | 28 | 40 |

Product World

Tungsten Carbide Inserts For TBM Tunnel Boring Machine

Designed, Developed and Produced according to customer demands

Key words:

Classification:

Tungsten Carbide for Geological and Mining

Product accessories:

Hotline:

Tungsten Carbide Inserts For TBM Tunnel Boring Machine

Tungsten Carbide Inserts Tips for TBM Tunnel Boring Machine Tools

Tungsten Carbide Shield Cutters ,TBM cutters are mainly used for construction of urban railway, traffic tunnel like metro, utility tunnel for supplying, emission and others.

The grades of our TBM inserts achieved ideal balance between wearing and impacting. Moreover with excellent corrosion resistance.

Common grades include YG8, YG8C, YG9C, and YG11C.

Main Cutter

Left-right Cutter

Long Cutter

Technical Specifications for Shield Machine Cutters

✅ Material: Adopts high-purity virgin tungsten carbide powder with a content of 99.95%.

✅ Performance: Exhibits excellent wear resistance and impact resistance.

✅ Particle Selection:

---- For rocks with high hardness and large impact loads, coarse-particle tungsten carbide (WC) is used as the raw material.

---- For rocks with low impact loads, medium-particle tungsten carbide (WC) is selected as the raw material.

Cutter Types and Cutting Principles

Shield machine cutters are generally classified into two types based on cutting principles: disc cutters and cutting blades (these two types can be further subdivided according to the surrounding rock properties and cutting purposes in tunnels).

Disc Cutters: Their cutting principle relies on crushing rock through extrusion, mainly used for rock tunnel excavation. When encountering loose strata with large gravel (particle size > 400mm) reaching a certain proportion, disc cutters can also be applied. Additionally, in complex geological conditions where rocks (with moderate strength) and general soil (clay or sand) appear alternately, disc cutters may be used, such as in composite shield machines.

Cutting Blades: Their cutting principle involves generating axial (along the tunnel advancing direction) shear force and radial (tangential direction of cutter head rotation) cutting force on the excavated soil as the shield machine advances and the cutter head rotates, continuously cutting the soil in front of the excavation face. Cutting blades are generally suitable for loose strata such as sandy gravel, sand, and clay with particle sizes less than 400mm.

Applications and Working Principle of Shield Machines

A shield machine is underground tunnel construction equipment that can operate without affecting surface conditions, significantly improving construction feasibility, reducing costs, and protecting surface heritage buildings and other structures. It is widely used in urban rail transit, highway/railway tunnels, cross-river/cross-sea tunnels, and hydropower project tunnels.

The underground working principle of a shield machine is somewhat similar to that of a daily electric shaver. It is equipped with a circular cutter head at the front, on which numerous cutting teeth (shield teeth) are installed. During operation, it coordinates with hydraulic jacks, as the jacks push forward, the main drive of the cutter head rotates to excavate the soil layer. The cylindrical shell of the shield machine provides temporary support for the excavated tunnel, followed by slurry circulation, lining, and backfill grouting operations.

WNiFe, Szie 2.5~180mm, 17.0~18.65g/cc, Machined, 30x20x15mm,50x20x15mm,60x20x15mm

WHA, High-density, WNiFe / WNICu, 17.0~18.5g/cc, Standard & Non-Standard, Support Customization

WHA, 17.0~18.5 g/cc, Dia 2.5~260mm, Non-toxic

Consulting price

Thank you for your trust in the northern alloy! Please fill in your requirements and we will provide you with service wholeheartedly.

* Note: Please be sure to fill in the information accurately and keep the communication unblocked. We will get in touch with you as soon as possible.